- Seestrasse 25,

8702 Zollikon - +49 (0) 151 / 19 17 86 75

svenloogen@lesstec.ch

Lesstec offers high-quality and complete disinfection of drinking water pipes. The treatment of the pipe with the L.E.S.S. disinfection system aims at the formation of a healthy, natural and unaffected biofilm, which remains stable when the pipe material is later used with clean drinking water and guarantees an inconspicuous microbiological finding.

Three-stage, fully comprehensive disinfection of drinking water pipes:

These three combinable processes sustainably remove germs and invertebrates

Any piping and piping materials, especially:

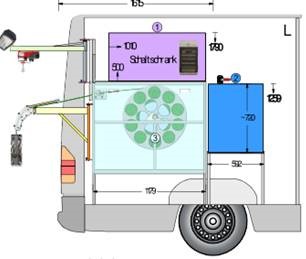

Workspace Control room (control station)

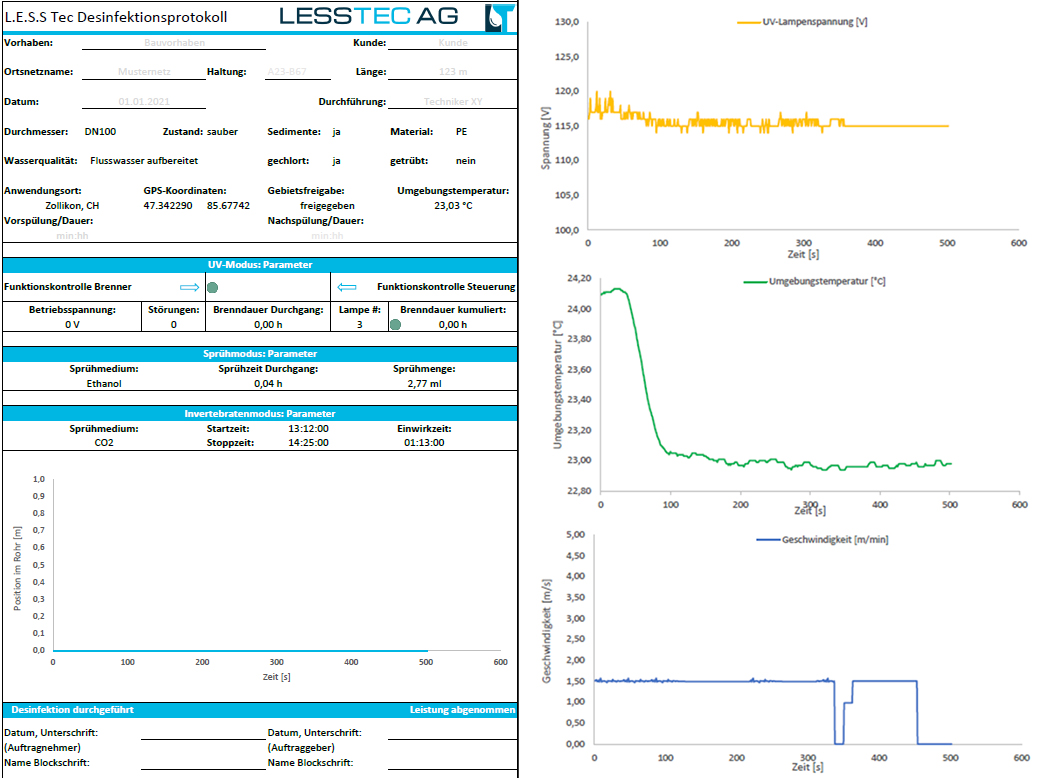

The logging of each of the three procedures guarantees a complete record and allows the output of a disinfection protocol.

The bactericidal effect of UV-C radiation is based on the fact that it efficiently destroys the DNA of viruses, bacteria and germs. Multiplication of the pathogens is no longer possible, so that comprehensive disinfection is guaranteed and re-germination can be prevented. No chemicals are used and thus the environment is protected. During the disinfection process using UV-C radiation, no harmful by-products are produced and overdosing is ruled out.

The disinfection performance is fast and sustainable. This leads to a time and cost advantage compared to conventional disinfection methods. Sustainable disinfection can be guaranteed in just one pass.

Treatment with the L.E.S.S. disinfection system stands for: